Material Handling

& Barcoding

CTI Material Handling Systems are built around barcode identity and our information management products like TFFIS. We custom design each system to meet the unique process layouts of your equipment.

& Barcoding

CTI Material Handling Systems are built around barcode identity and our information management products like TFFIS. We custom design each system to meet the unique process layouts of your equipment.

CTI Material Handling Expertise

CTI Offers Intelligent Material Handling

CTI Offers Intelligent Material Handling

Benefits of Intelligent Material Handling

- We have a proven track record with systems that reliably convey, track, and collect data for large product volumes (> 60,000 tires/day/station)

- We have extensive experience routing tires to machines, special handling stations, palletizing stations and other product sorting systems based on scheduling, customer, and tire processing results.

- We have information management software ready to assist, monitor, and report tire processing

CTI Offers Intelligent Material Handling

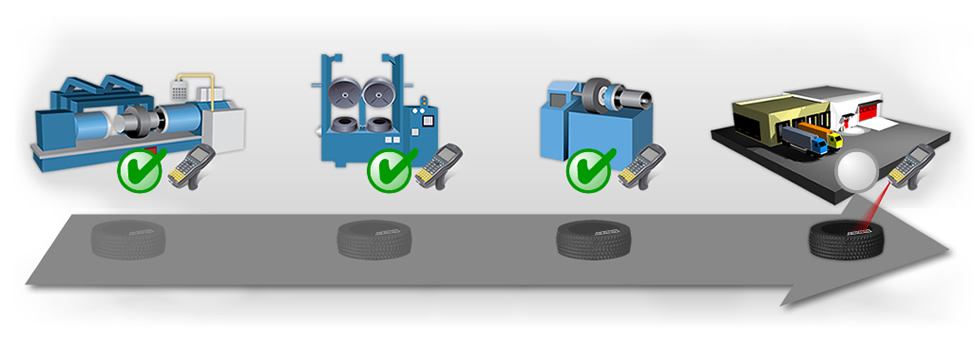

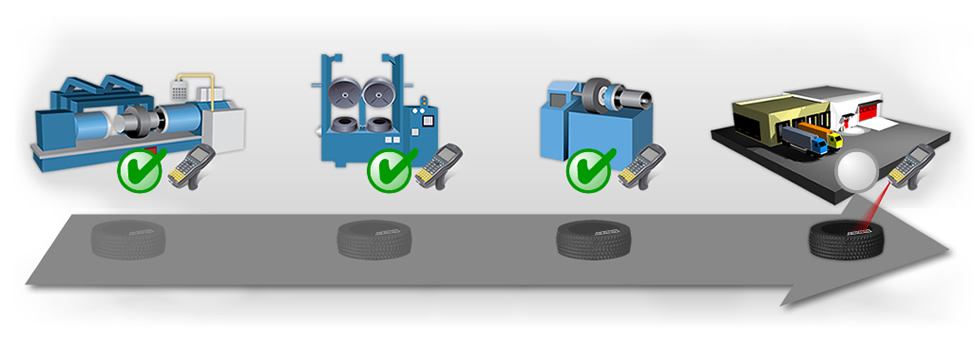

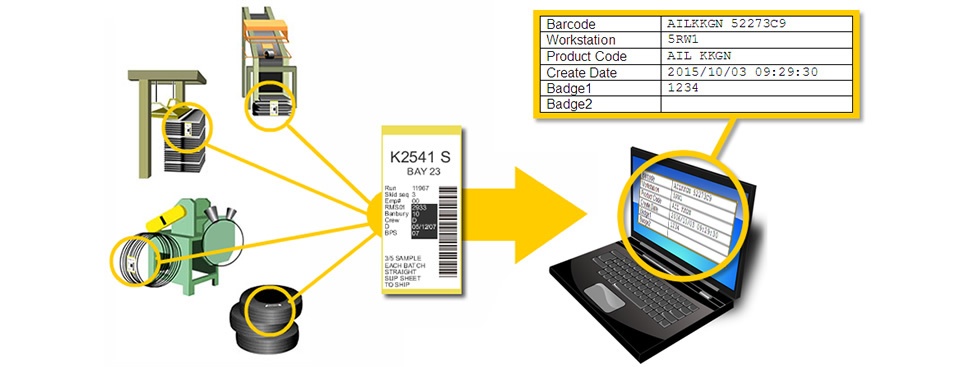

CTI Offers Intelligent Material Handling- Strategically-placed barcode readers identify product arriving at a process location

- Information management software that acquires and tracks process data for each identified product

Benefits of Intelligent Material Handling

- Convey product to scheduled, available destinations

- Convey product around unnecessary processes (bypass)

- Validate product at a processing point, before processing begins

CTI Material Handling Services

- Assistance in choosing the barcode format and symbology that best fit your operations

- Engineering to define requirements, such as machine capacity, production flow, and tire characteristics

- Development of specifications, installation drawings, and project management plan

- Design of conveyor layout and control architecture

- Production of floor level PLC controls and software

- Project management, including startup assistance

- Information management, including web-based user interface

Barcoding & Product Traceability

Why Invest in Product Barcoding?

Barcoding for Tire Manufacturers

Begin barcoding by attaching barcode labels to products:

You can barcode products individually (green tires) or packaged in groups (beads), and either apply pre-printed barcode labels supplied on rolls, or attach individual barcode tags printed “on demand“ as inventory is produced.

You can also barcode packaged products. These applications usually utilize “on demand” barcode labels that automatically print as inventory is produced. When you attach barcodes to your products, you identify them. Now you can track products as they are produced, moved, tested, and consumed.

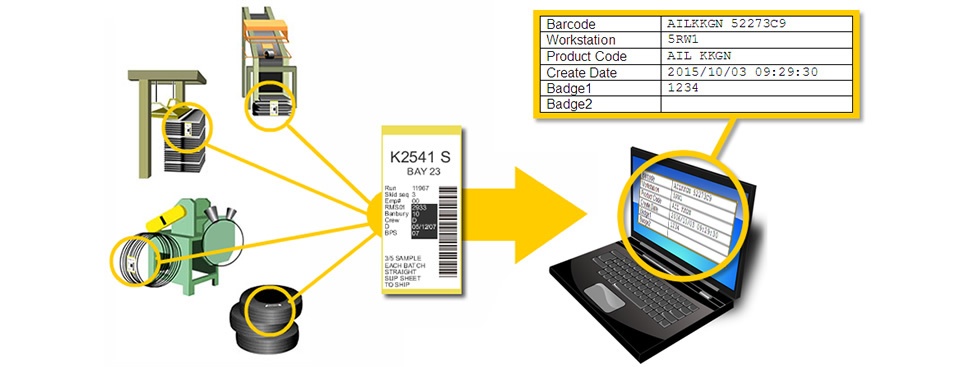

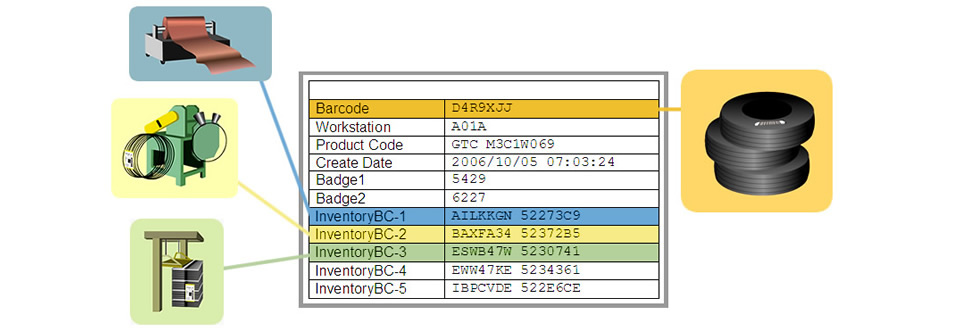

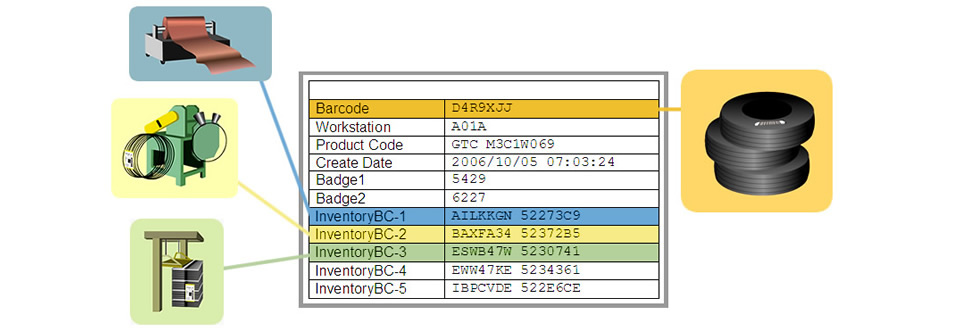

When you store product data keyed by barcode number, you create Product Traceability.

Because components were scanned at a building machine, the database record also links to component product data. To retrieve this information, just scan the tire barcode label.

Each product barcode record also links to detailed machine and operator data. CTI can customize data to fit your organization.

Why Invest in Product Barcoding?

- Enables intelligent material handling and a necessary element of product traceability

- Builds foundation for automatic inventory management

- Allows mixed mode (lot size 1) vs. batch mode processing in the final finish area

- Improves response to customer and product quality issues

Barcoding for Tire Manufacturers

Begin barcoding by attaching barcode labels to products:

- Raw materials that become rubber

- Rubber that becomes components

- Components that become tires

- Tires that go to your customers

You can barcode products individually (green tires) or packaged in groups (beads), and either apply pre-printed barcode labels supplied on rolls, or attach individual barcode tags printed “on demand“ as inventory is produced.

You can also barcode packaged products. These applications usually utilize “on demand” barcode labels that automatically print as inventory is produced. When you attach barcodes to your products, you identify them. Now you can track products as they are produced, moved, tested, and consumed.

When you store product data keyed by barcode number, you create Product Traceability.

Because components were scanned at a building machine, the database record also links to component product data. To retrieve this information, just scan the tire barcode label.

Each product barcode record also links to detailed machine and operator data. CTI can customize data to fit your organization.

CTI, A POLING GROUP COMPANY

Founded in 1978, CTI has been a valuable resource for large industries. Since 2001, we've expanded the capabilities of Poling Group tire equipment, including uniformity and geometry testing machines.

©2026 Commercial Timesharing, Inc. All Rights Reserved

CTI is a Poling Group company.